Tuck points for hard floors

-

Diamond milling disc underfloor heating for hard floors

As low as €78.65 €65.00Diamond milling disc for underfloor heating, suitable for hard floors such as concrete and floor tiles.

Available (see options) in:- 120 x 15 mm

- 120 x 17 mm

- 130 x 11 mm

- 130 x 15 mm

- 130 x 17 mm

Learn More -

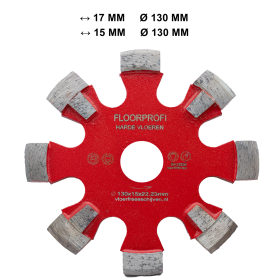

Diamond saw blade, tuck point, for cutting (milling) in extra hard floors

€87.12 €72.00Floor milling disc for underfloor heating in extreme hard concrete floors.

- Suitable for milling underfloor heating in extremely hard floors such as hard concrete and floor tiles

- We recommend water cooling during milling ≈

- Professional quality

- Width milling disc: 17 or 15 mm

- Diameter: 130 mm

- Center hole: 22.23 mm

- Type: V-disc

- Number of segments: 8

Diamond tuck points for underfloor heating in hard floors milling discs.

Suitable for milling underfloor heating into concrete, floor tiles and other hard floors.

Diamond tuck points underfloor heating for hard floors

Professional quality

Width of tuck point: 11, 15 or 17 mm

Diameter: 120 mm or 130 mm

Center hole: 22.23 mm

Type: V-disc

Number of segments: 12

What is a diamond tuck points for underfloor heating in hard floors?

Diamond tuck points underfloor heating for hard floors are used for milling grooves in, for example, concrete floors and tiles. Tuck points are mounted on a floor heating milling machine that you can rent or purchase yourself. With the diamond tuck points underfloor heating for hard floors it is possible to grind exactly enough space in the floor for laying underfloor heating pipes without having to rebuild the entire floor. The milling machine follows the laying plan via a predetermined pattern, so that the floor is precisely processed to mill the correct groove for the underfloor heating pipes.

Advantages of milling underfloor heating:

The advantage of using this milling method is that the underfloor heating pipe is placed directly on the surface of the floor, the room can heat up faster and more efficiently.

The total costs are also usually lower when choosing milling than other underfloor heating systems. After all, there is no raising of the floor or additional costs for new thresholds and door frames.

Types of diamond tuck points underfloor heating for hard floors:

The diamond tuck points underfloor heating for hard floors usually have a width of 17 mm for 16 mm pipes, 15 mm for 14 mm pipes or 11 mm for 10 mm pipes so that they perfectly fit the pipe diameter of your choice. This allows you to mill and install the underfloor heating accurately and efficiently.

High-quality diamond tuck points underfloor heating for hard floors:

Dimensions: 15 x 120 mm, 17 x 120 mm, 11 x 130 mm, 15 x 130 mm, 17 x 130 mm.

The diamond tuck points underfloor heating for hard floors is suitable for installing underfloor heating (diamond milling blade, floor milling disc, milling disc underfloor heating) in concrete floors, tiles and other hard floors . The tuck points are used to install underfloor heating yourself and is balanced for optimal and comfortable usage.

Usage of diamond tuck points underfloor heating for hard floors:

With this milling disc you can mill slots yourself in existing hard floors using an underfloor heating milling machine . The diamond tuck points underfloor heating for hard floors have 12 or 8 support segments, depending on the availability of water-cooling of the milling machine. During usage the slot width remains constant and curves can be sawn effortlessly.

Dry milling, usage without watercooling

≈ Usage with watercooling: